Understand how an offset printer works

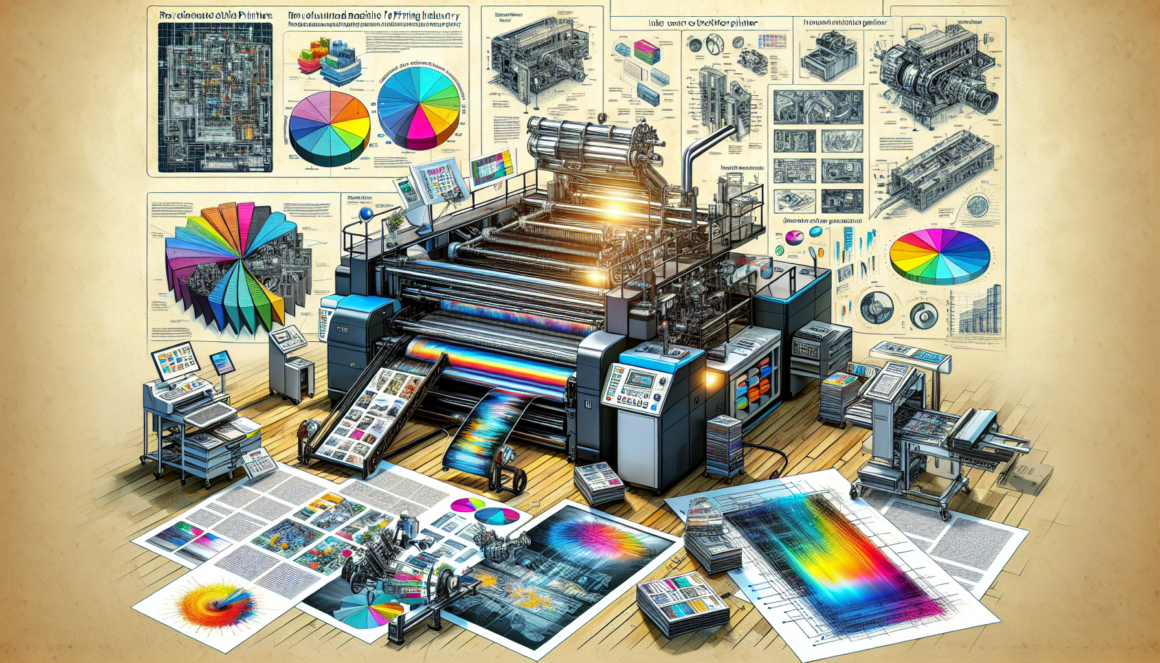

Offset printing is an essential pillar in the world of professional printing. Its scale and high performance attract companies of all sizes keen to combine quality and efficiency. But how does a offset printer, and what advantages does it offer to its users?

The particularities of offset technology

The essence of offset printing is based on the principle of ink and water repulsion. The machine uses printing plates carefully engraved bearing the image to be printed. These plates are first moistened with water, then inked. The ink adheres only to the parts of the plate representing the image, while the wet areas, corresponding to the non-printable parts, repel the ink.

In the process, the image is transferred from the plate to a cylinder covered with a soft rubber called a blanket, before finally being pressed onto the paper support. This indirect process is also at the origin of the term “offset”, meaning “shifted” in English.

Recent progress and examples in this area

Facilities such as those of Prévost Offset in Saran, underline the continued commitment in this sector. Technological advances, including Speedmaster SX102, launched by Heidelberg, perfectly illustrate the evolution of offset printers towards greater efficiency and a better ecological compatibility. This innovation, and others such as Speedmaster CX 104, enable businesses like yours to tackle a diverse range of printing jobs with consistent quality.

Investments, such as those made by the Socosprint printing company in a new offset press or by Estimprim, which injected 7 million euros into both offset and digital printing, prove that this technology remains at the heart of strategies industrial.

The benefits of offset printing for your business

So what are the benefits for your business? Offset printing offers superior print quality, with sharp images and vivid colors, which is essential for any communication material that wants to be professional and attractive.

Additionally, she is famous for her consistency: once the machine is set, subsequent prints will be identical to the first, a major advantage for large print runs. And that’s not all, offset printing can also be synonymous with eco-friendly printing, since companies are committed to reducing their environmental footprint without generating additional costs for the customer.

Depending on the volumes to be printed, production costs can become very advantageous, because unit costs decrease with the increase in the number of copies. This aspect, combined with the versatility machines such as the 5-color SX 52, allows printing to be adapted to various needs without sacrificing quality.

Offset printing as a solution to current challenges

In a context where it is important to reinvent oneself, companies like the Graphus printing company have relaunched themselves thanks to a strategy of distancing. Offset printing not only meets today’s needs; it adapts and evolves to offer solutions that meet today’s challenges, such as the integration of production methods combining sustainability and innovation.

The offset press operator, displaying in-depth technical know-how inherited from William Hardouin and other professionals in the sector, is also at the heart of this precision mechanics, guaranteeing that each print meets the most demanding standards.

By recognizing the importance ofefficiency, from the flexibility, and the sustainability In terms of printing, your business will be well positioned to take advantage of the benefits that an offset printer offers. It is a decision which, far from being an expense, turns out to be a wise investment for your presence on the market and for the brand image of a dynamic and modern company.

Offset printing: superior quality for professional prints

Offset Printing: Superior Quality for Professional Prints

When it comes to professional printing, technology offset stands out as an undisputed reference. Renowned for its precision and the constancy Based on its results, offset printing meets a crucial need: that of producing high-quality prints in large quantities, while optimizing costs. Professionals demand faithful reproduction and impeccable rendering, criteria that offset printing is particularly well equipped to meet.

The Indispensable Know-How of the Margeur

All the magic of offset printing is based on a harmonious combination of cutting-edge technology and human know-how. In this regard, the role of feeder is crucial. The true conductor of the offset press, the feeder ensures the correct positioning of the sheets of paper and the careful adjustment of the margins. Its expertise guarantees the uniformity of the prints and is a guarantee of a final result without defects. Companies seeking excellence for their printing cannot ignore the importance of this profession, a true pillar of quality in offset printing.

The Offset Printer: A Sustainable Investment for Varied Printing

Adaptability and versatility are also among the indisputable strengths of theoffset printer. Indeed, this technology also excels inmedium to large format printing, making it possible to respond to diverse requests, from standard brochures to large-scale posters. This ability to adapt is essential for companies wishing to remain competitive in a market where visual communication needs are ever more varied and demanding.

Profitability and Performance: The Advantages of Offset for Businesses

In terms of profitability, offset printing stands out as a wise option. Once the initial setup is complete, costs per unit decrease significantly when running large numbers. This makes it a strategic solution for companies that wish to maintain a high quality while managing in a manner effective their printing budget.

In summary, offset printing remains unrivaled for professionals looking for high-quality prints. It combines the excellence of artisanal know-how with technological advances, providing real added value to companies concerned about their brand image. By leveraging this technology, the promise of powerful and professional visual communication becomes a concrete reality.

Profitability and cost-effectiveness of offset printing for large series

The winning equation of offset printing for high volumes

When it comes to producing large numbers of prints, the offset printer becomes a real ally for printing professionals. A fundamental question arises: how to take advantage of the profitability and the cost-effectiveness in the case of massive production? The answer lies in the very essence of offset technology, which combines high quality And efficiency as the quantities increase.

Amortization of initial costs: an undeniable advantage

It is common knowledge in the printing industry that the >offset printing requires an initial investment to create project-specific printing plates. However, this investment quickly becomes negligible as the number of impressions increases. Thus, for large series, the cost per copy decreases considerably, making the process extremely competitive compared to alternative methods such as digital printing.

Unrivaled print quality maintained at scale

An indisputable advantage of the offset printer lies in its ability to provide an impeccable level of detail and consistency of quality over large volumes. This quality factor is crucial for companies which do not compromise on the final appearance of their communication media. The usefulness of such a level of perfection no longer needs to be demonstrated when brand image is at stake.

Speed of execution and adaptation: high demands and deadlines met

Faced with the need to respond to high demands while respecting tight deadlines, companies find offset printing a high-performance solution. The speed of the offset production line, once the plates have been prepared, ensures a continuous high-speed production flow, guaranteeing compliance with deadlines and therefore customer satisfaction.

Saving ink: cost reduction and respect for the environment

Thanks to its advanced technology, offset printing uses ink with great economy, minimizing waste and contributing to reduce costs printing. This optimal management of ink is not only beneficial for the budget, but it also promotes an ecological approach by limiting excess material and reducing the environmental footprint of production.

Conclusion: Offset printing, a solution of choice for large series

In summary, for companies planning to produce documents or communication materials in large quantities, offset printing represents a first-rate option. From the amortization of initial costs to optimized resource management, including the guarantee of consistent quality and rapid production, offset printing combines economic and practical advantages for any large-scale project. If your goal is to combine efficiency and budget control, there is no doubt that this printing technique has its place in your production strategy.

Comparison with other printing technologies

In the diverse world of printing technologies, theoffset printer stands out for its remarkable ability to produce high quality prints in large quantities. For businesses seeking performance and reliability, understand the fundamental differences between offset and competing technologies such as laser printing and3D printing is crucial.

The emergence of sophisticated models such as the Elegoo Neptune 4 Plus in 3D printing or the laser prowess illustrated by laser technology, reveal the constant evolution of the printing market. These technological advances, associated with machines like the Artillery Sidewinder

Offset Printing Vs Laser Printing

L’offset printing features unrivaled image quality, accurate color reproduction and a cost per page that decreases with quantity. On the other hand, laser printing, explained in detail on specialized platforms, offers notable printing speed and rapid start-up, suitable for more moderate volumes with a need for flexibility.

Offset: Unrivaled Quality for Large Series

Where offset shines is in its incredible ability to handle very large print runs with a consistency in quality that is simply unattainable for other technologies. In addition, the unit price of prints decreases significantly as the number of copies increases, a considerable advantage for businesses with high print volumes.

Laser precision for medium prints

Laser printing, on the other hand, excels in environments where versatility and responsiveness are required. Capable of handling medium-sized print runs with great precision and instant start-up, it impresses with its ease of use and adapts perfectly to the varied needs of a dynamic business.

The 3D Printer: A Revolution for Custom-Made Objects

Another category shaking up the printing landscape is that of3D printing. Models like the Creality Ender-3 V3 KE are revolutionizing the manufacturing of custom and complex components, providing unmatched production flexibility across many industries. However, unlike offset printing, 3D printing serves entirely different purposes, focusing on the creation of three-dimensional objects and not the printing of graphic documents.

Operating Costs to Consider

In addition to technical and qualitative aspects, the total cost of ownership should be considered. While offset may require a larger initial investment, its operating costs tend to be lower for large productions, making the return on investment more attractive in the long term.

Ultimately, the ideal technology will depend on the specifics and requirements of each company. By analyzing the advantages and constraints of each printing technology, internal managers, like Marine, will find it difficult to ignore the robustness and efficiency of theoffset printing for their extensive printing needs.

In the quest for an optimal printing solution, it is crucial to look at the detailed characteristics of each technology, taking as references recent models and tests such as those carried out on the Anycubic Kobra Neo or the Qidi -Max 3. This makes it possible to precisely understand the performance offered by each type of printer, and to decide in favor of the technology most aligned with the strategic objectives of the company.

Impact of offset printing on sustainability and the environment

The Green Revolution in Printing: Offset Printing

The graphics industry has relied for a long time on traditional printing without necessarily taking into account its environmental impact. Today, a green revolution is underway, advocating environmentally friendly offset printing. Focus on the major advances in this technique and how it is reinventing sustainability in the professional printing sector.

Natural Pigments for a Respectful Print

The use of natural pigments in offset printing opens up new promising ecological perspectives. These pigments, at the forefront of sustainable innovation, offer an alternative to traditional inks which often contain harmful chemicals. Pigments from renewable resources not only reduce the carbon footprint of printing but also maintain color vibrancy and quality.

The Eco-Flyer: Pioneer of Ecological Printing

The growing demand for greener communication has led to the development of eco-flyers. This concept perfectly illustrates the industry’s commitment to eco-friendly printing. Produced on recycled or responsibly sourced papers, with vegetable-based inks, eco-flyers embody the fusion of quality and environmental responsibility.

Eco-responsible Packaging: An Example to Follow

Packaging is another area where offset printing is making waves. Through initiatives like that of M-real, companies are discovering that a efficient packaging must not be to the detriment of the ecosystem. By optimizing printing processes and using sustainable materials, packaging can both protect the product and preserve the environment.

The Art of Sustainability: Junoa and Local Engagement

The impact of offset printing is not limited to large productions; it also embraces local projects dedicated to culture and heritage. Junoa, an Angevin project, symbolizes this approach with its collection ofvintage posters. Carefully designed using offset printing, these art pieces illustrate how small-scale productions can be both aesthetically pleasing and environmentally friendly.

Conclusion: Towards a Greener Future

Offset printing is no longer synonymous with waste and pollution. On the contrary, it becomes a driving force for change towards a more responsible industry. By adopting practices such as the use of natural pigments, the creation of eco-flyers, and the design of eco-designed packaging, offset printing is establishing itself as an ally of sustainability and the environment. Companies sensitive to these values, just like our protagonist Marine, will find in offset printing a solution that meets their expectations of quality and eco-responsibility.

Leave a Reply