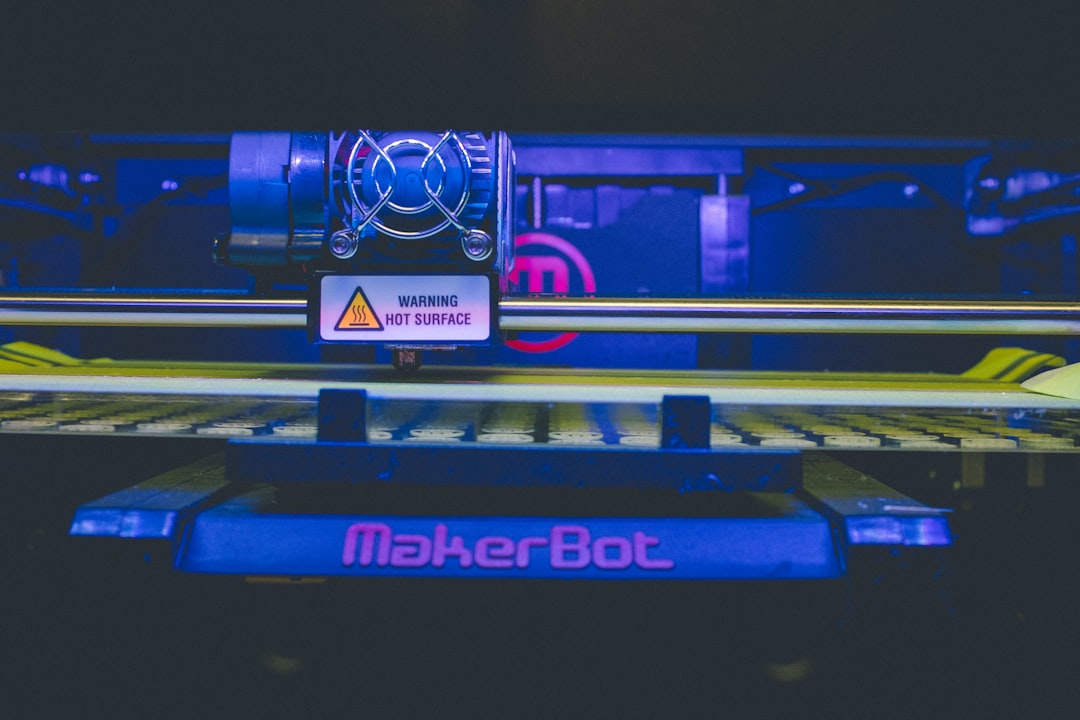

3D printing has grown exponentially in recent years, radically transforming the industrial landscape. We have observed that this technology not only reduces production costs, but also speeds up the design and manufacturing process. Indeed, thanks to 3D printing, companies can create prototypes quickly and efficiently, allowing them to test ideas before moving to mass production.

This ability to rapidly iterate on designs has paved the way for unprecedented innovation in diverse industries, ranging from aerospace to medicine, automotive and architecture. Additionally, 3D printing offers unparalleled flexibility when it comes to product customization. We have found that companies can now meet the specific needs of their customers by producing one-off parts or in small batches, which was previously difficult and expensive with traditional manufacturing methods.

This increased personalization has also allowed businesses to stand out in an increasingly competitive market. By integrating 3D printing into their processes, they can not only improve their operational efficiency, but also strengthen their market position by offering tailor-made solutions that meet consumer expectations.

Summary

- 3D printing is increasingly used in the professional sector for the manufacture of prototypes, custom parts and production tools.

- Artificial intelligence is integrated into professional printers to improve printing accuracy, speed and quality.

- Advances in eco-friendly and sustainable printing include the use of recycled materials and eco-friendly manufacturing processes.

- Connectivity and the Internet of Things are increasingly important in professional printing for remote management, preventive maintenance and consumables management.

- Advances in print speed and quality enable faster renderings and finer details, improving efficiency and customer satisfaction.

The integration of artificial intelligence into professional printers

The impact of artificial intelligence on professional printing

The integration of artificial intelligence (AI) into professional printers represents a major breakthrough that is transforming the way we print. We have noticed that AI helps optimize printing processes by analyzing data in real time and automatically adjusting settings to ensure optimal print quality. For example, some printers are now able to detect anomalies during the printing process and make instant corrections, reducing the risk of defects and material loss.

Increased autonomy and reliability

This adaptability makes printers more autonomous and reliable, which is essential for businesses that rely on continuous production. Additionally, AI also facilitates workflow management in professional printing environments. We have observed that intelligent systems can predict material and maintenance needs, allowing businesses to plan their operations more efficiently.

Increased productivity and efficiency

This results in reduced downtime and increased overall productivity. Additionally, AI can analyze user preferences and suggest suitable templates or designs, making the printing process even more intuitive and accessible.

A new era of innovation

In short, the integration of artificial intelligence in the professional printing sector paves the way for a new era of efficiency and innovation.

Advances in eco-friendly and sustainable printing

Growing awareness of environmental issues has led to significant advances in the field of ecological and sustainable printing. We’ve found that many companies are now committing to eco-friendly printing practices, using recyclable and biodegradable materials. For example, some 3D printers use filaments made from recycled plastics or even biomaterials, reducing their carbon footprint while maintaining high print quality.

This transition to sustainable materials is essential to meet the growing expectations of environmentally conscious consumers. Additionally, printing technologies are evolving to minimize waste and optimize resource use. We have observed that some printers are now equipped with systems that allow waste generated during the printing process to be recovered and reused.

This not only reduces the volume of waste produced, but also contributes to more efficient use of materials. By integrating these sustainable practices into their operations, businesses can not only improve their brand image, but also realize significant savings in the long term. The future of professional printing therefore looks bright, with a growing emphasis on sustainability and environmental responsibility.

The growing importance of connectivity and the Internet of Things in professional printing

Connectivity and the Internet of Things (IoT) are playing a crucial role in transforming the professional printing industry. We’ve noticed that modern printers now come with connected features that allow remote management and real-time monitoring. This means we can track printer status, manage material inventory and even initiate print jobs from anywhere, significantly improving our operational efficiency.

This connectivity also allows for seamless integration with other systems within the company, facilitating collaboration between different departments. Additionally, IoT provides the ability to analyze data generated by printers to optimize performance. We have found that through these analytics, businesses can identify trends and patterns that allow them to improve their printing processes.

For example, they can determine which types of work are most frequent or which materials are used most often, which helps to better plan purchases and reduce costs. In short, connectivity and IoT are transforming not only the way we print, but also the way we manage our day-to-day printing operations.

Advances in print speed and quality

Recent technological advances have significantly improved the speed and quality of printing in the professional sector. We have observed that new generations of printers are capable of printing at much higher speeds while maintaining an exceptional level of precision. This is especially important for companies that need to quickly produce prototypes or parts to meet market demand.

With these advancements, we can now produce complex prints in record time, allowing us to remain competitive in a dynamic business environment. Along with these speed gains, print quality has also seen a significant improvement. New technologies enable fine details and impeccable finishes, which are essential to meet the high demands of professional customers.

We’ve found this to be particularly true in industries like aerospace or medicine, where every detail counts and precision is paramount. By combining increased speed and superior quality, we are able to offer printing solutions that meet the varied needs of the market while meeting the tight deadlines imposed by our customers.

New finishing and personalization features in professional printing

The evolution of the professional printing sector has also been marked by the emergence of new finishing and personalization features. We have found that modern printers now offer an expanded range of options for customizing finished products to customers’ exact specifications. Whether through varied color printing, specific textures or even interactive additions like integrated QR codes, these features allow businesses to stand out in a saturated market.

This ability to personalize every aspect of the final product strengthens our competitive position while meeting growing consumer expectations. Additionally, these new features aren’t just limited to aesthetics; they also improve the functionality of printed products. For example, some technologies allow functional elements to be incorporated directly into the printing process, such as electronic circuits or integrated sensors.

This paves the way for a new generation of intelligent products that can interact with their environment or provide real-time data. By integrating these innovations into our offerings, we can not only meet current market needs, but also anticipate future trends and position ourselves as leaders in the field.

The impact of augmented reality and virtual reality on professional printing

Augmented reality (AR) and virtual reality (VR) have begun to play a significant role in the professional printing industry, transforming our approach to design and prototyping. We have observed that these technologies allow designers and engineers to visualize their creations in an immersive environment before they are even printed. This not only facilitates the creative process, but also allows potential problems in the design to be quickly identified, reducing the time and costs associated with physical iterations.

Using AR and VR, we can explore different design options and make changes in real-time, which significantly improves our efficiency. Additionally, these technologies also provide an enriched customer experience during the process of purchasing or displaying printed products. We’ve found that some companies are using AR to allow customers to interact with their products before they’re even manufactured.

For example, a customer can view a piece of furniture in their own space using a mobile application before placing an order. This approach not only improves customer satisfaction, but also reduces the risk of returns or post-purchase dissatisfaction. By integrating augmented and virtual reality into our professional printing processes, we are able to offer significant added value to our customers while optimizing our internal operations.

Security and Privacy Trends in Professional Printing

As the business sector evolves toward greater connectivity and technological integration, security and privacy become major concerns for us all. We’ve seen that businesses now face a growing number of potential cybersecurity threats, including hacking of sensitive data stored on connected printers or when transferring information between different systems. To counter these risks, it is essential that we have robust protocols in place to protect our data throughout the printing process.

Additionally, it is crucial that we are aware of data protection regulations that are constantly evolving. We have observed that some industries are subject to strict standards regarding the management of sensitive information, requiring increased vigilance when processing and storing print-related data. By taking a proactive approach to security and privacy, we can not only protect our assets but also build trust with our customers and business partners.

In short, as we continue to innovate in professional printing, it is imperative that we incorporate these essential considerations to ensure a secure and sustainable future for our industry.

To deepen your understanding of technology trends in professional printing, I recommend checking out a related article that explores the benefits of digital printing technology for businesses. This article details how innovations in this sector can optimize processes, reduce costs and improve print quality in a professional context. To read this article, please click on the following link: Digital printing technology: what are the benefits for your business?.

FAQs

What are the technological trends in the field of professional printing?

Technology trends in professional printing include the increasing adoption of 3D printing, the integration of artificial intelligence to improve printing processes, and the development of eco-friendly printing solutions.

How does 3D printing impact the field of professional printing?

3D printing is revolutionizing the field of professional printing by enabling the manufacturing of complex and personalized objects, reducing production costs and deadlines, as well as the possibility of creating prototypes quickly.

How is artificial intelligence used in professional printing?

Artificial intelligence is used in professional printing to optimize printing processes, improve print quality, predict equipment maintenance needs, and analyze data to improve operational efficiency.

What are the ecological printing solutions emerging in the professional field?

Green printing solutions include the use of recycled materials, reducing the energy consumption of printing equipment, and the development of environmentally friendly printing technologies, such as water-based printing. vegetable ink.

Leave a Reply