Key steps for effective preventive maintenance

In a professional world where continuity of operations is crucial, the reliability of your printer fleet is essential. To ensure flawless operation, the preventive maintenance is the preferred strategy. Follow these key steps to ensure longevity and the optimal performance of your printing equipment.

Rigorous planning of the maintenance schedule

The first step toward successful preventative maintenance management is establishing an accurate schedule. This schedule must be adapted to the printing volume and the specificities of each device. It is recommended to schedule regular check-ins, for example, on a quarterly basis, to avoid any impromptu interruption to your activities.

Thorough cleaning of essential components

Regular cleaning of printer components is fundamental to maintaining print quality and device durability. Items such as the pickup roller, print heads, and paper path need special attention. The use of suitable products will guarantee effective cleaning while preserving the health of your equipment.

Checking and updating software

The proper functioning of a printer does not only depend on its mechanics, but also on the software that controls it. Make sure you always have the latest firmware version and drivers, in order to benefit from improvements in terms of functionality and security. This process significantly contributes to minimizing the risk of malfunctions.

Preventive replacement of wearing parts

Professional printers include parts that wear out over time. To avoid breakdowns, it is essential to replace them proactively. Components like toner cartridges, image drums, and maintenance kits should be carefully monitored and changed before they show signs of weakness.

Consumables management

The quality of consumables has a direct impact on your prints and the condition of your equipment. Favor branded supplies or certified to preserve the performance of your printer fleet. In addition, precise monitoring of consumable levels will help you avoid unplanned downtime and ensure constant availability of necessary resources.

User training

Proper use of the printer by all users is just as important as maintenance performed by technicians. Training staff on good usage practices and simple daily maintenance actions helps reduce the risk of breakdowns and optimizes the lifespan of the device.

By following these key steps, your business will benefit from a reliable printing infrastructure capable of efficiently meeting all your business needs. There preventive maintenance is a strategic investment that will support productivity and operational excellence.

Identify critical components to monitor

Preventive maintenance of professional printers: issues and advantages

There preventive maintenance of your professional printers is an essential performance lever for your business. Indeed, anticipating potential breakdowns and ensure the longevity of the material constitute a wise strategy to ensure optimal continuity of your activity. Not only does this help avoid unplanned downtime that can occur during an outage, it also means cost containment by reducing unforeseen expenses related to emergency repairs or equipment replacements.

Critical components to monitor for proper maintenance

Among the components essential to the proper functioning of a printer, some deserve special attention. Here is a non-exhaustive list of vital parts:

- Print head : A central element which directly impacts the quality of prints and which can become clogged or altered over time.

- Training rollers : Essential to ensure the correct routing of paper, they avoid jams and other inconveniences.

- Ink or toner cartridges : Not only do you need to ensure that they are well stocked, but also that they remain in good condition and do not leak.

- Memory and Firmware : Periodic updates help prevent software malfunctions and maintain performance.

Monitoring and maintaining these components may seem complex, but it is an investment that will ensure the reliability and longevity of your printing equipment.

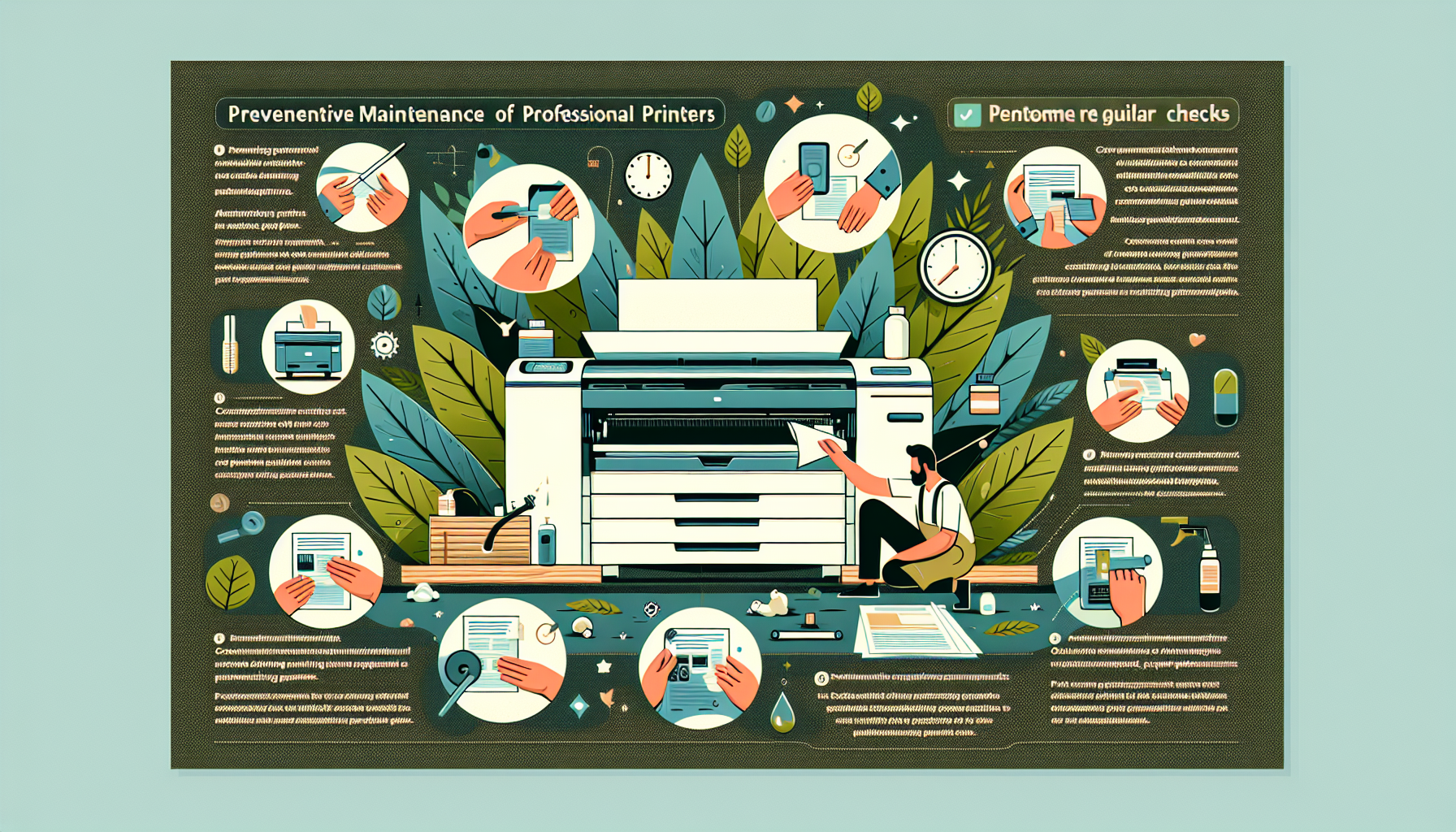

Verification protocol: ensuring consistency of performance

Set up a verification protocol Regular operation is essential to detect any anomaly before it causes a major malfunction. This protocol includes visual inspection of parts, quality testing of prints, and monitoring of system error messages. Also be sure to clean internal components as recommended by the manufacturer to avoid the accumulation of dust and debris that can impair the operation of your printer.

Preventive renewal: a winning strategy

Sometimes replacing certain parts even before they show signs of failure can be a relevant preventive approach. This preventive renewal components such as fusers or maintenance kits, helps avoid unplanned downtime and ensures consistent quality.

Partnership with a professional service: peace of mind

It is advisable to collaborate with a service provider specializing in the maintenance ofprofessional printers. These experts have know-how that ensures a precise diagnosis and rapid and effective interventions. Their services often include maintenance contracts that adapt to your specific needs, ensuring optimal management of your printing equipment.

Ultimately, preventive maintenance is more than just upkeep; it is a strategic approach that contributes to the performance and competitiveness of your company. Taking this path means choosing efficiency and peace of mind for all your professional printing solutions.

Plan the preventive maintenance schedule

Preventive maintenance of professional printers: the essence of successful planning

Professional printers are the cornerstone of document management within a business. To ensure optimal performance and extend their lifespan, preventive maintenance is not only recommended, but essential. Establishing a preventative maintenance schedule is a smart approach that prevents unexpected interruptions and ensures smooth printing operations.

Step 1: Identify your printer maintenance needs

Before diving into the actual planning, it is essential to know the specifics of your printer fleet. Each model may require different maintenance depending on its use and technical characteristics. Start by making a list of your equipment, noting how often it is used, the types of regular service required, and the manufacturer’s recommendations for maintenance. Keep in mind that preventive maintenance involves the cleaning, THE replacement of wearing parts and the feature check.

Step 2: Create a specific maintenance schedule

Once maintenance needs have been established, it is time to convert them into a program of planned actions. Creating a personalized maintenance schedule allows interventions to be scheduled at appropriate times, thus minimizing the risk of disruption. Be sure to include:

– Regular inspections to detect possible anomalies before they cause failures.

– Frequent cleaning of sensitive components such as print heads and feed rollers.

– Periodic replacement of parts such as ink or toner cartridges, drums, and maintenance kits.

– Software updates to ensure continued compatibility with the operating systems and software used in your business.

Step 3: Integrate maintenance into workflows

For the maintenance schedule to be truly effective, it must be integrated into the daily operations of the company. Inform all stakeholders, from administrative team to technical staff, of the importance of following the established schedule. Automated reminders and coordination with internal or external maintenance departments will ensure that each intervention takes place according to plan without disrupting the normal course of activities.

Step 4: Review and adjust the maintenance schedule

Preventive maintenance is not static; it requires periodic reassessment to keep pace with the evolving needs of your printer fleet. Analyze the effectiveness of your current plan based on incidents, maintenance costs and user feedback. Adjustments may consist of spacing out or bringing together maintenance intervals, or modifying procedures based on observed performance.

Align maintenance schedule with business objectives

Preventive maintenance of professional printers should aim to support your business objectives by ensuring maximum uptime and consistent print quality. In short, a well-designed maintenance schedule provides peace of mind and becomes a profitable investment that improves efficiency and productivity. Take the time to set up a tailored maintenance schedule and you will quickly see the positive impact on your daily and long-term operations.

Recommended cleaning procedures for the printer

The essentials of preventive maintenance

To guarantee the longevity and performance of your printing fleet, the preventive maintenance is a key step. Regular maintenance prevents breakdowns and ensures consistent print quality, a significant factor in the daily efficiency of your business. Think of it as health insurance for your equipment; By practicing regular maintenance, you avoid unexpected and costly problems. This rigor in maintenance also gives your team the peace of mind they need to focus on their tasks without unforeseen interruptions.

Cleaning critical components

The first step towards effective cleaning is to focus on the critical components of your printer. Print heads, pickup rollers and toner cartridges are at the heart of your device’s operation. These elements require special attention and must be cleaned with suitable products and a precise method. This helps prevent any buildup of particles or paper residue that could affect print quality or cause paper jams.

Cleaning frequency for optimal performance

- General cleaning: To be carried out every month to dust the exterior of the printer and the paper trays.

- Printheads: Clean every three months or after each cartridge replacement to ensure crisp print quality.

- Pickup rollers: Inspect and clean at least twice a year to avoid paper feeding problems.

Suitable cleaning products

Always use cleaning products recommended by the manufacturer. This is essential to avoid damaging sensitive components. Alcoholic solutions or cleaning foams are often recommended, accompanied by lint-free cloths or special sticks to access difficult areas. It is crucial to prioritize products specific to professional printing to ensure compatibility with the materials and designs specific to these devices.

Step-by-step cleaning procedure

A cleaning procedure methodical method ensures efficient maintenance while protecting your equipment. Here’s a step-by-step approach:

- Unplug the printer and let it cool if necessary.

- Clean the exterior with a soft, slightly damp cloth.

- Carefully remove the removable elements and proceed to their separate cleaning.

- Use lint-free sticks and cloths to clean internal areas.

- Inspect the print heads and clean them according to the manufacturer’s instructions.

- Replace all components and test the device to ensure proper operation.

Raise team awareness of the importance of cleaning

There awareness of your team is also a determining factor in the success of preventive maintenance. Establishing a routine and providing adequate training on cleaning procedures ensures that each member is able to contribute to the preservation of printers. Accessible documentation or scheduled reminders can greatly help in this regard.

In summary, regular preventive maintenance carried out according to the rules of the art is the guarantee of sustained performance and reliability of your printing fleet. It is an investment that ultimately translates into savings in time and money, preventing untimely interruptions and unforeseen repair costs. A well-maintained printer means peace of mind for everyone and productivity maintained at its highest level.

Replacement of wearing parts and stock management

Preventative maintenance of professional printers: a necessity for business continuity

Optimizing the performance and longevity of your professional printer fleet undoubtedly requires rigorous preventive maintenance. Ensuring periodic replacement of wearing parts is not only good practice; it is a strategy that guarantees you reduce the risks of unforeseen outages and maintain constant efficiency in the management of your prints. A preventive maintenance schedule, when intelligently integrated into your company’s routines, becomes an essential tool to promote optimal continuity of operations.

Anticipation and replacement of wearing parts: a pillar of preventive maintenance

Wear is inevitable on the mechanical and electronic components of a professional printer. Parts such as feed rollers, copier drums, print heads or maintenance kits should be closely monitored and replaced before they compromise the quality of your prints or the reliability of your equipment .

To avoid unplanned downtime, it is essential to identify the expected lifespan of each component and schedule their preventive replacement. Printing equipment suppliers often offer maintenance programs that can include managing these replacements, ensuring that replacement parts are always of adequate quality and installed in the appropriate time frame.

Effective management of spare parts stock: a strategic asset

Maintaining an adequate inventory of spare parts is an often underestimated aspect of preventive maintenance. Effective inventory management not only involves having the necessary parts in case of replacement but also avoiding costly overstocking. There is a delicate balance between ready availability of essential components and a wise investment in your inventory.

A good practice is to analyze the historical data of your equipment to anticipate the needs for wearing parts. Inventory management tools based on predictive algorithms can significantly simplify this task today, allowing you to adjust your inventory based on actual wear and consumption trends.

Process optimization and substantial savings

A program of preventive maintenance well-oiled is not just about replacing parts at the right time; it must also integrate seamlessly into your operations so as not to disrupt your workflow. When correctly implemented, preventive maintenance not only contributes to the longevity of your printers but also saves money through reduced service interruptions and reasonable consumption of spare parts.

Each printer has specific requirements, and a personalized strategy depending on the model and frequency of use will ensure that your investment in preventive maintenance is wisely allocated. Regular review of this strategy will ensure its continued adaptation, best meeting the evolving needs of your business.

In summary, integrating effective preventive maintenance and optimal inventory management are fundamental elements to maximize the productivity and performance of your professional printing solutions. This not only ensures consistent print quality but also controls your costs, two essential aspects for any business concerned with its sustainability and efficiency.

Leave a Reply