Identify common problems and their causes

In the fast-paced world of industrial printing, broken equipment can be the cause of a real shortfall. Understand the common problems and their origins is crucial to keeping your printer in optimal working order and avoiding unexpected interruptions.

Defective Ink or Toner Supply

The heart of a printer, whether inkjet or laser, lies in its ability to dispense ink or toner. A faulty power supply results in faded, streaked, or missing printouts altogether. Among the causes are the ink cartridges or poor quality toner, nozzles clogged with particles, or problems with the laser drum.

Mechanical and Wear Problems

The components of an industrial printer wear out over time. The feed rollers may lose grip, causing frequent paper jams. Moving parts may require lubrication or replacement to counteract the unusual noises often indicating wear or disruption.

Electronic and Software Problems

A faulty motherboard, connectivity issues, or outdated drivers can cause communication errors between the printer and networked devices. An update of the firmware or reinstallation of software printing are potential solutions to these technical obstacles.

Deteriorated Print Quality

If your prints have defects, take a close look at the printheads and alignments. Paper quality and printer settings should be matched to the requirements of the print job to prevent quality degradations.

Tips for Effective Troubleshooting

– Inspect cartridges or toners regularly and replace them if necessary.

– Clean the print heads and check for obstructions.

– Maintain mechanical parts and replace worn parts before they cause breakdowns.

– Periodically update software and firmware.

– Use materials and supplies recommended by the manufacturer to avoid incompatibilities.

In an industrial printer, accurately detecting failures and understanding their underlying causes is essential for successful troubleshooting and preventing future failures. Don’t forget the importance of after-sales service reliable, which can be a considerable asset in the ongoing maintenance of your printing equipment.

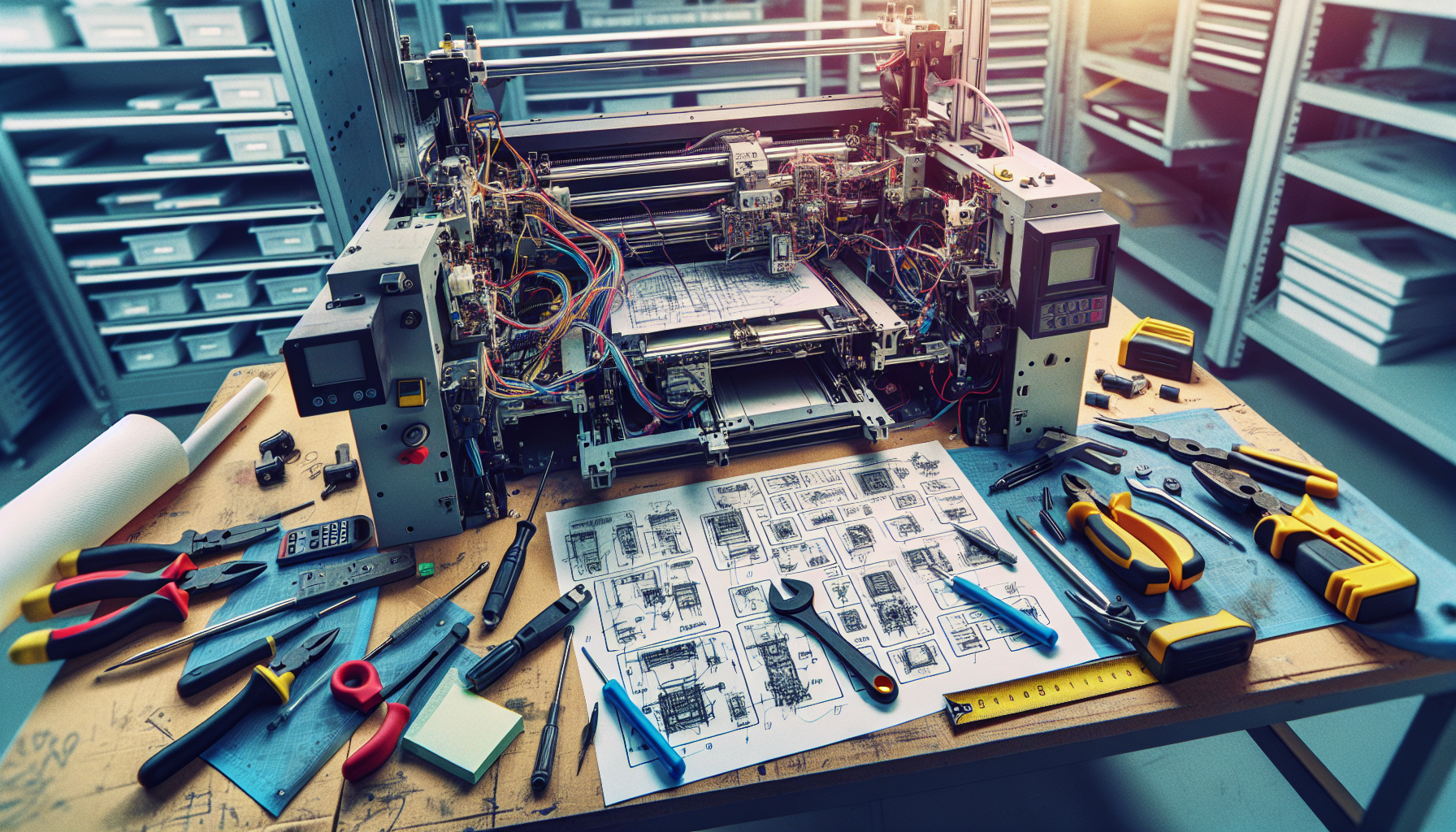

Preparation and tools for troubleshooting

In an industrial environment, every minute of production downtime can result in significant losses. So, when we talk about troubleshootingindustrial printers, speed and efficiency are essential. But for your procedure to be successful, adequate preparation is essential. Find out here how to anticipate and what tools are necessary to keep your equipment in perfect working order.

Anticipate to better manage

Good management of print flow requires preparation and anticipation. First of all, you need to know your equipment well. Always have the user manual at hand and be familiar with the instructions specific to the model in question. Furthermore, a maintenance bill or well-accounted repairs will not only allow you financial monitoring but will be valuable in anticipating future maintenance and repairs.

The importance of accounting in this context is often underestimated. Keeping the register of your interventions up to date will allow rigorous monitoring performance of your printers and anticipate maintenance needs. To understand the details of the accounting entries related to repairs, it is advisable to refer to resources specific to this area.

Equip yourself adequately

Obtain the right tools for the specific model of your industrial printer. A basic kit should include:

- A precision screwdriver set for the special screws often used in these devices

- Tweezers and wire cutters for handling or cutting small components

- A multimeter to check the integrity of circuits and electronic components

- Antistatic gloves to handle sensitive components without risking damage from electrostatic discharge

- An antistatic mat for working safely on electronic components

Also make sure you have spare supplies, such as ink cartridges or print heads, to replace worn parts without delay. This will ensure your printing business resumes quickly.

Build a troubleshooting plan

Effective troubleshooting often begins well before the problem occurs. Equip yourself with a business plan robust, including a technical risk management component, is crucial. This involves predicting different scenarios and developing strategies to minimize the impact of possible malfunctions. Downloading business plan templates can be very useful for understanding the issues and structuring your approach.

In summary, a proactive approach to troubleshooting industrial printers involves in-depth technical knowledge of your equipment, rigorous accounting management of interventions, precise and complete tooling as well as a well-thought-out business strategy. By embracing these areas you will ensure the sustainability and efficiency of your industrial printer fleet.

Key steps for an accurate diagnosis

The reliability of your printing equipment is at the heart of your operational flow. When a breakdown occurs, the diagnosis must be as efficient as the equipment you use. Follow these key steps to accurately diagnose your industrial printer and get back to business quickly.

Initial Situation Assessment

Before diving into the technical twists and turns, careful observation is essential. Check for external signs of abnormality on your industrial printer, such as unusual noises, vibrations or burning smells. A visual inspection may reveal obvious problems such as paper jams or ink spills that require immediate attention.

Viewing the User Manual

Before carrying out any intervention, refer to the user manual of the device. This valuable companion contains essential information about error messages, standard troubleshooting procedures, and precautions specific to your printer model.

Analysis of Error Messages

THE error messages are key indicators of the source of the problem. Take note of any codes or messages displayed and consult the documentation to decipher their meaning. These messages can guide you directly to the solution, or at least point you in the right direction.

Checking Consumables

Consumable components such as ink cartridges, toners and paper should be checked regularly. Make sure they are installed properly, there are no ink leaks, and the quality of the print media meets the specifications. technical specifications recommended. Incompatibility or running out of consumables are often the cause of printing problems.

Review of Internal Components

If the previous steps did not resolve the problem, it is necessary to inspect the internal components. Turn off the printer and make sure it is secure before removing covers to access items like rollers, printheads, and electronic boards. An accumulation of dust or debris may prevent the device from functioning properly.

Functional Tests and Diagnostic Software

Software utilities built into or available from the manufacturer can assist in performing functional tests. These diagnostic tools perform a series of checks to evaluate different parts of the printer and spot anomalies. Run these programs while the printer is connected to a computer or network to get a detailed report on its status.

Maintaining Updates

An up-to-date industrial printer is a healthy printer. Make sure the firmware and drivers are the latest version available. Problems that initially appear serious can be easily resolved by a simple system update.

Consult Troubleshooting Experts

When all diagnostic options have been exhausted, it is time to call in the professionals. A service of technical support qualified has the tools and expertise necessary to troubleshoot complex or very technical cases. Don’t forget to explore the option of signing up for a maintenance contract for guaranteed peace of mind.

Speed and efficiency are the key words of industrial printer troubleshooting. Each step in this process increases your chances of returning to optimal production with minimal downtime. By implementing a systematic method, and supported by a solid knowledge of your equipment, you will be able to calmly face any technical challenge.

You have the power to ensure the performance and durability of your industrial tools. When technical glitches arise, a precise diagnosis is your precious ally for a quick and efficient return to normal.

Common Problem Solving Strategies

Managing industrial printers is a critical aspect in the workflow of any company relying on large, quality document production. Sudden printer shutdowns can cause costly downtime. This is why having problem-solving strategies in place is essential to minimizing downtime. In this context, let’s understand how to methodically and effectively address the most common difficulties with pragmatic solutions.

Print quality concerns

Print quality problems are often the first signs of a malfunction. Spots, streaks, or blurred text may indicate problems with the toner or ink. Before contacting a service center, check if the cartridges are full and correctly installed. Cleaning the print heads may also be necessary. In the case of irregular printing, examining the paper quality and printer settings is also a crucial step.

Communication errors

Communication between the computer and the printer is essential. Errors may occur during data transmission, causing erroneous or non-existent printouts. Make sure the connection cables are plugged in securely and the print drivers are up to date. Updating or reinstalling the printer software can resolve many communication issues.

Paper Jam Problems

One of the most common problems is paper jams. A paper clearance procedure must be undertaken carefully to avoid damaging the internal mechanisms of the printer. After removing the jammed paper, it is recommended to check the alignment of the paper tray and the condition of the pickup rollers which may wear out over time.

Improved sustainability

To prevent these situations, preventive maintenance is a beneficial practice. This includes regularly cleaning the printer, checking the status of components, and updating the firmware. Service and maintenance contracts with professionals can ensure regular checks and therefore extend the durability of your industrial printer.

Optimization of print flow management

In addition to directly solving physical problems, optimizing print workflow management can also reduce the risk of malfunctions. This can be achieved by monitoring print jobs, distributing workloads evenly across multiple printers, and using dedicated printing software that makes it easier to manage print queues.

Performance tracking

Implementing a printing fleet management system makes it possible to monitor the performance of each device. This can reveal usage patterns that predispose to certain issues, and thus enable a more balanced distribution of printing tasks.

Choice of rental for optimal performance

Renting industrial printers can be a wise strategy to benefit from high-quality machines without a heavy initial investment. Suppliers often offer troubleshooting services as well as included maintenance contracts, ensuring both performance and peace of mind.

Effective management of industrial printers requires a thorough understanding of the equipment and well-established maintenance and rapid response procedures. Faced with these challenges, a partnership with specialized service providers proves to be a valuable solution. Not only do these experts provide fast and efficient support, but they also offer advice that helps anticipate problems for an uninterrupted workflow. Close attention to detail and a proactive approach are the keys to keeping your printers in optimal condition, contributing to the productivity and success of your business.

Preventative maintenance to reduce breakdowns

In an industrial world where every minute of downtime can mean substantial economic losses, equipment reliability is a priority. At the heart of this productive ecosystem, industrial printers are essential pillars. To ensure their proper functioning, the preventive maintenance proves to be a winning strategy, both from the point of view of performance and cost control.

Preventive maintenance, in line with the predictive maintenance, shares the ambition to detect the warning signs of dysfunctions. This approach relies on regular inspections and planned interventions, which helps minimize the risk of unplanned breakdowns and extend the lifespan of devices.

Technicians specializing in predictive maintenance are trained to interpret data and translate it into proactive corrective actions. A job of the future which combines the use of cutting-edge technological tools with in-depth knowledge of the field. Their role is crucial to ensure uninterrupted and quality production.

The economic benefits of preventive maintenance

A poorly maintained industrial printer can lead to costly production downtime and quality defects. Studies show that understanding real cost of unreliable equipment is central to justifying investment in preventive maintenance. By extending the operating time between failures, production losses and excess repair costs are avoided.

It is therefore essential, as part of this approach, to understand the importance of the responsibility that a company incurs when faced with faulty installations. Thus, a properly implemented preventive maintenance program can transform an expense item into a truly profitable investment.

Understand and apply types of maintenance

Industrial maintenance comes in several types, each meeting specific needs. Among the 5 main types maintenance, there are corrective, preventive, conditional, predictive and evolutionary. It is by judiciously combining these different methods that companies industrialize the durability of their equipment.

Preventive maintenance involves carrying out checks and replacements of parts based on a pre-established schedule, before problems arise. It is an essential pillar in site maintenance industrial companies which seek to guarantee a safe and efficient working environment.

Technology and preventive maintenance

The digital age has transformed maintenance strategies. The adoption of the cloud and Big Data now makes it possible to collect and analyze an imposing quantity of data to refine preventive maintenance practices. For example, the company ThyssenKrupp managed to prevent breakdowns in its elevators through innovative use of these technologies.

Applying these advances to the field of industrial printers means being able to predict potential failures with increased accuracy, thereby reducing service interruptions and optimizing resource utilization. This results in a tangible improvement in productivity and customer satisfaction.

In conclusion: a global and anticipatory strategy

Preventive maintenance is far from being an unnecessary expense. It is a strategic tool in the arsenal of companies keen to optimize their production. Implemented with insight, it makes it possible to anticipate breakdowns, just as EDF seeks to anticipate risks in its nuclear power plants.

For those responsible for maintaining industrial printers, it is time to consider prevention as an investment that secures long-term operations and strengthens the competitiveness of their business. Becoming proactive rather than reactive is no longer an option but a necessity to ensure continuity of service and unparalleled performance.

Leave a Reply