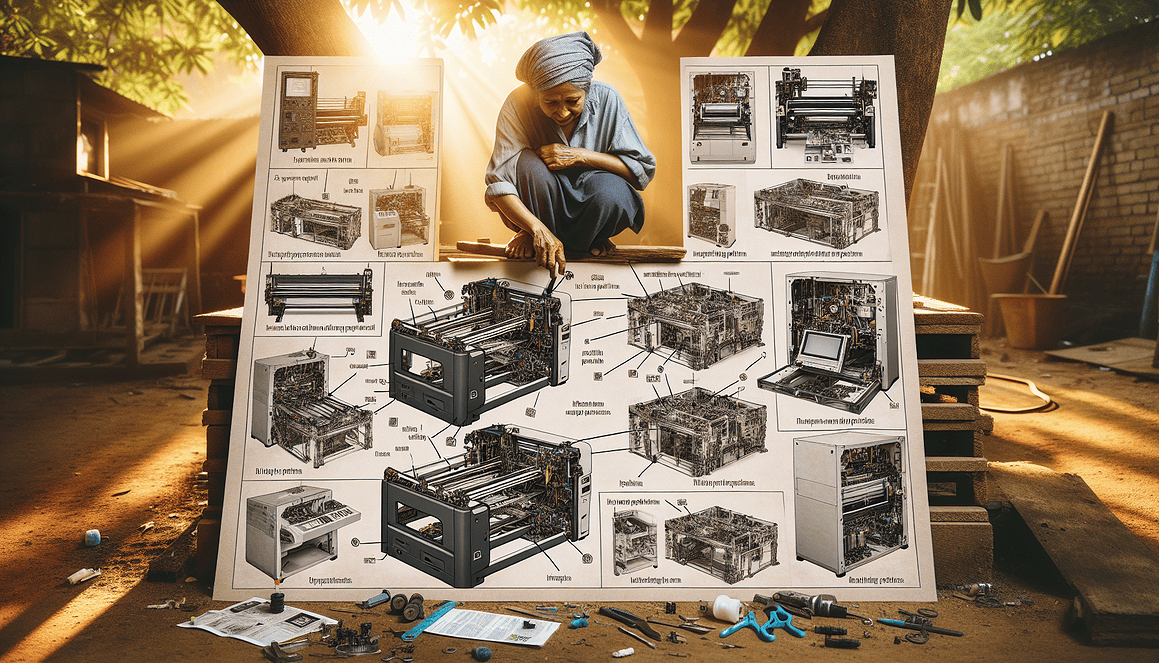

Initial Diagnosis: Identifying the Printer Problem

In the world of industrial printing, optimal operation of equipment is crucial for the continuity of production. A failure can cause serious disruption to your operations. This is where the repair of industrial printers takes on all its importance. Before embarking on a hasty repair, a initial diagnosis is necessary to accurately target the source of the problem.

Assessment of the situation

First of all, take the time to observe the behavior of your printer. Signs such as unusual noises, error messages on the control screen or degraded print quality are all clues. Be sure to document these signals to facilitate the process of diagnosis.

Consultation of the user manual

An often overlooked but essential point is consulting the printer manual. This document often contains valuable information regarding error messages and troubleshooting procedures. As a guide designed by the manufacturer, it should be your first point of reference before commencing any repair.

Checking accessible components

Carefully examine the accessible components of your printer. This includes ink or toner cartridges, print heads, paper feed rollers, and any visible connections. Check to see if these items require cleaning, replacement, or simply repositioning.

Analysis of error messages and codes

Error messages displayed on your printer should not be taken lightly. Each code has a very specific meaning which can direct you to the exact nature of the malfunction. A careful search for these codes in the technical documentation or on the manufacturer’s website is a crucial step in diagnosis.

Running a self-test cycle

Many industrial printers are equipped with a self-test function. This allows you to run an internal diagnostic that can reveal specific problems with certain parts of the machine. Consult the user manual for instructions on how to perform this test and interpret its results.

Maintenance history inventory

A well-kept maintenance history on your machine can be an indicator of recurring problems or components that may be damaged. This predictive approach can save you from future inconveniences and effectively guide repairs.

Testing connection settings

If your printer is connected to a network or other devices, make sure all connection settings are configured correctly. A faulty connection can be the source of many problems, often underestimated when trying to repair an industrial printer.

Consideration of the operating environment

The environment in which your printer operates can influence its operation. Excessive humidity, extreme temperatures or the presence of excessive dust are all factors that can affect the performance of your equipment. Make sure the environment complies with the manufacturer’s recommendations.

By summarizing all these steps, you establish a complete initial diagnosis which will effectively guide repair interventions. Remember that a industrial printer is an investment for your business; Taking the time to properly diagnose a problem can save you from exorbitant repair costs and prevent production downtime. Once the initial diagnosis has been made, you will be in a better position to decide whether an on-site repair is possible or whether the expertise of a after-sales service is required.

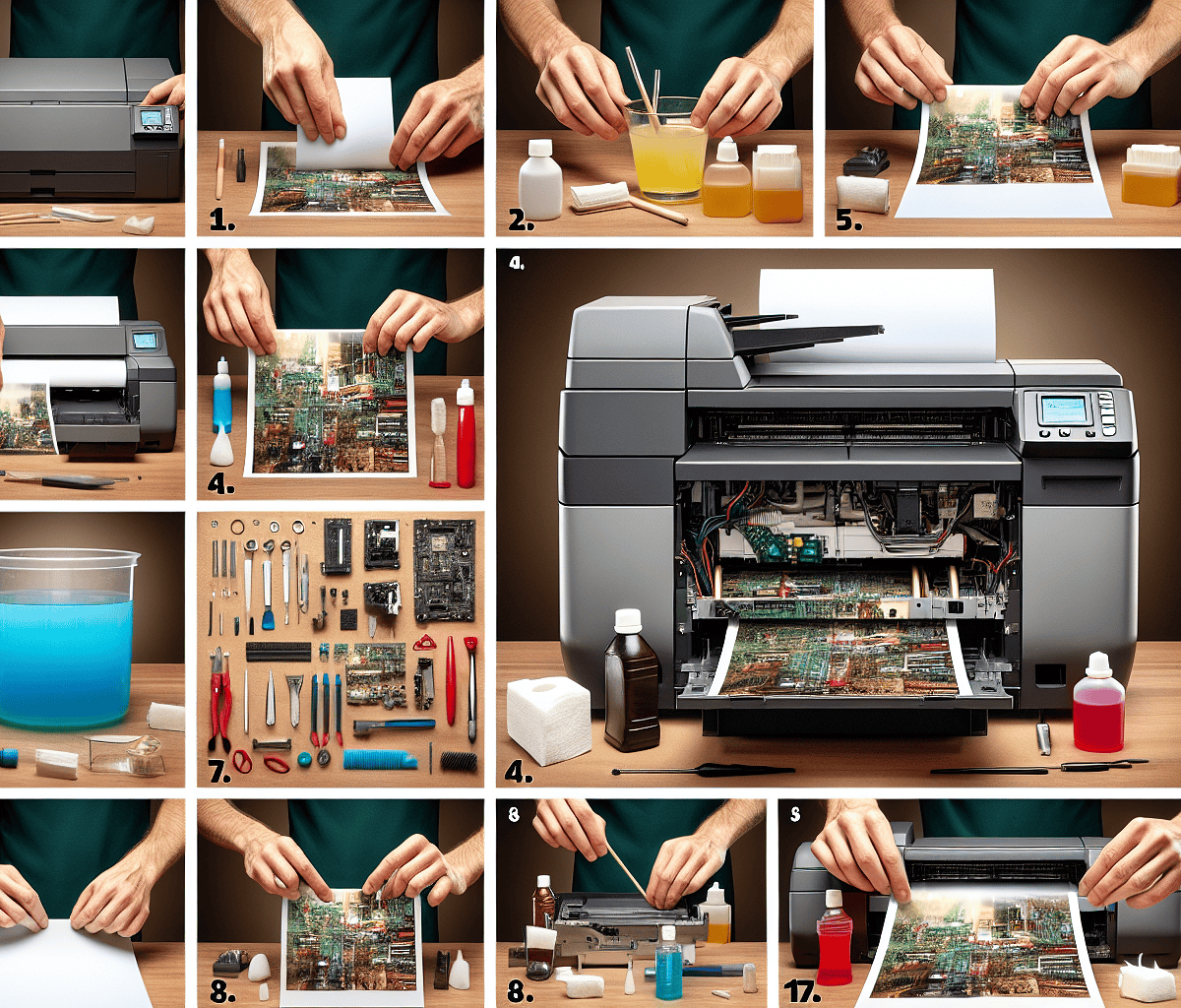

Tools and materials needed for repair

In the world of professional printing, the selection and maintenance of equipment is of paramount importance. Every component of your printer fleet must perform optimally to ensure uninterrupted productivity and high-quality results. However, faced with high print volumes and natural wear and tear, even the most robust machines may need repairs. To ensure the longevity of your equipment and prevent costly downtime, here is a handy guide to the essential tools and materials for industrial printer repair.

Diagnostic Tools

Before starting any repair, it is crucial to determine the origin of the malfunction. To do this, equip yourself with a multimeter which will allow you to check the integrity of the electrical circuits. Diagnostic software specific to your printer model may also be required to access error codes and follow troubleshooting instructions.

Repair Kit

A screwdriver kit with different bits is essential to dismantle the panels and access the internal components of the printer. Additionally, tweezers can be useful for removing small parts or stuck residue, while wire cutters will help replace damaged ties or cables.

Replacement Materials

Make sure you always have spare parts compatible with your production equipment. This includes print heads, rollers, belts and ink or toner cartridges. Good inventory management will allow any defective part to be replaced quickly.

Cleaning Products

Cleaning is a fundamental step in maintenance. Use products designed for industrial printers, such as non-abrasive solvents to clean print heads and anti-static cloths to remove dust without damaging electronic circuits.

Technical Manuals and Online Resources

A wide range of information is at your fingertips, particularly thanks to detailed guides and supplier manuals. These valuable resources offer instructions specific to your printer model and can guide the repair step-by-step.

As a professional aware of the importance of perfectly functioning equipment, never neglect the use of appropriate tools and materials. Effective repair not only ensures the continuity of your operations, but also the quality of your prints and the satisfaction of your customers. Invest in the best tools and materials and ensure your staff is well trained in their use to maintain the performance of your industrial printers.

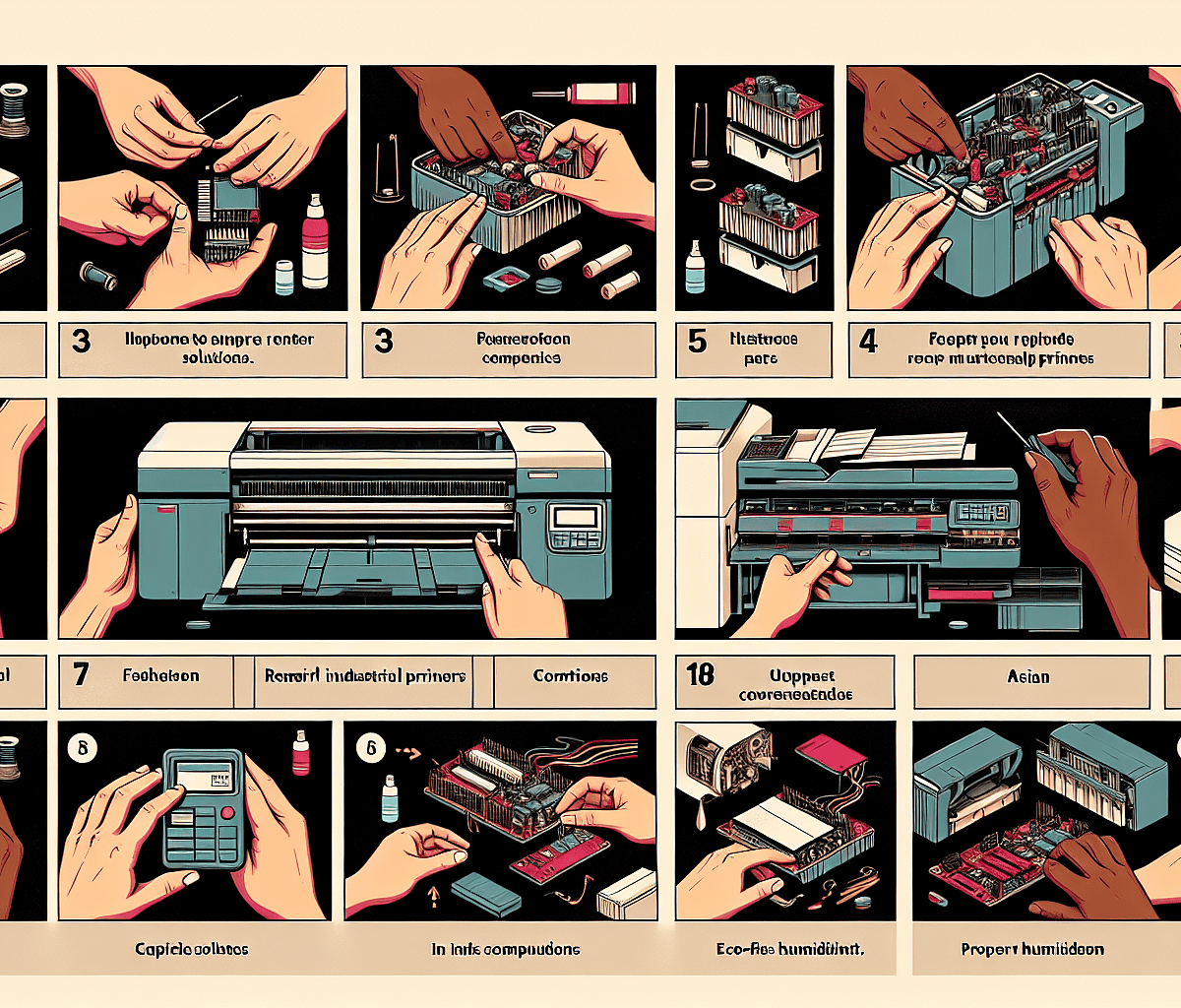

Troubleshooting Steps: Detailed Procedure

First Steps to Resolution: Determine the Problem

When an industrial printer shows signs of malfunction, it is crucial to first accurately identify the issue. Is it a print quality problem, a paper jam, or more serious systematic errors? Take a minute to notice the symptoms: ink bleeds, error messages, unusual noises. These clues will direct you to the root cause and help you find the right solution.

Consulting the User Manual: Your First Resource

The user manual for your industrial printer is a gold mine of information specific to the model you are using. If it is a common problem, the guide can provide you with a procedure to troubleshooting step by step. This manual is also useful for understanding certain error codes specific to your hardware. Keep in mind that each model, whether among the 150 that you could access, has its particularities in terms of maintenance and repair.

Verification and Maintenance of Key Components

In this mechanical ballet, each part plays an essential role. Start by checking items that are easily accessible. Replace empty cartridges or toners, clean clogged print heads, and make sure the loaded paper meets the required specifications. A regular maintenance can prevent many problems.

Diagnosing Electrical and Connectivity Problems

Malfunctions are not always mechanical. Sometimes they come from electrical problems. Check the power and connectivity cables for damage, and make sure the printer has good connectivity with the network of your business. A firmware update can fix unexpected malfunctions and improve the performance of your machine.

When to Call a Professional?

Some repairs go beyond standard expertise and require professional intervention. If the problem persists after following the first steps of the resolution, do not hesitate to contact a service center. repair approved. Specialized technicians have the experience and tools to diagnose and repair problems that guides don’t always cover in detail.

Sustain the Performance of your Industrial Printer

The longevity of your industrial printer requires careful maintenance and proper use. Take a proactive approach by establishing a maintenance schedule regularly and by training your staff in the optimal use of the equipment. This way, you will maximize the durability of your printer and the quality of your prints.

Finally, for those planning for the long term and wishing to solidify their knowledge in business management, the breadth of resources available such as business plan templates can be of invaluable help, not only to structure the maintenance strategy but also to optimize all printing flows within your structure.

By taking into account these practical tips to respond effectively to the vagaries of an industrial printer, you not only ensure the continuity of your production but also the quality of your investment in printing equipment.

Safety Tips for Repairing an Industrial Printer

When the time comes to repair an industrial printer, several elements must be considered to guarantee not only the effectiveness of the troubleshooting but also and above all the safety of the workers and the equipment. Here are some essential practices to put in place.

Electrical insulation and personal protection

Before any intervention, it is crucial to ensure that the device is completely disconnected from any power source. This avoids the risk of electric shock and allows you to work in a safe environment. Even when using modern technologies such as 3D pens, which provide impressive repair precision, electrical insulation remains a priority.

In addition, personal protective equipment is required: insulating gloves, safety glasses and appropriate work shoes. Every detail counts to prevent accidents.

In-depth knowledge of hardware

In-depth knowledge of the equipment is essential. Before starting the repair of your industrial printer, it is important to rely on the user manual or on specialized resources, which can offer precise assistance adapted to the complexity of industrial systems.

Compliance with maintenance protocols

Strict application of maintenance protocols is a guarantee of safety and efficiency. These procedures often come from experience and continuous innovation in the sector, like what theGeneva industry through the circular economy. Learning from best industrial practices can contribute to more responsible and sustainable maintenance.

Use of appropriate tools and parts

The use of appropriate tools and spare parts is essential. This not only ensures the sustainability repairs but also safety during and after the intervention. Unsuitable tools can cause irreparable damage or accidents.

Have a suitable work area

The work area should be organized, clean and uncluttered to facilitate movement around the industrial printer and minimize the risk of dropped tools or other incidents. The organization and maintenance of an optimal workspace is as crucial as the troubleshooting itself.

Workflow management

Ensuring good workflow management is an often overlooked but essential aspect. Plan each step of the repair to avoid unnecessary operations that could cause additional risks. To learn more about process structuring and optimization, it may be interesting to consult resources like Tech Me Up! for additional advice on flow management in an industrial setting.

Training and updating of knowledge

Continuing training of technical staff is essential. Ensure that repair teams are regularly trained and updated on the latest innovations and regulations in force, for safe intervention that complies with current standards.

By following these recommendations, you will be able to approach the repair of your industrial printer with confidence, guaranteeing the safety of everyone and the longevity of your equipment. Never forget that prudence is the ally of efficiency in any industrial environment.

Prevention of future breakdowns and regular maintenance

Preventing future industrial printer failures

Every professional who relies on industrial printers knows that a failure can lead to detrimental consequences for workflow and productivity. This is why the prevention is a crucial aspect to ensure the proper functioning of your printing equipment.

Understanding Common Causes of Failure

Above all, it is essential to recognize the roots of the problems that may be affecting your industrial printer. Often, it is the lack of cleaning and of maintenance, debris accumulation, improper use, or problems with the ink or parts supplier.

Let’s set up a maintenance routine

Install a regular maintenance program is probably the most effective measure to prevent malfunctions. This must include:

- Regular cleaning of critical components.

- Checking and replacing worn parts before they cause failure.

- Updating software to benefit from the latest improvements and fixes.

Staff training

Make sure the operators are properly trained to use the industrial printer. Improper handling can not only cause immediate failure but also accelerate the wear of components.

Regular maintenance for the longevity of the industrial printer

A well-maintained printer is synonymous with reliability and durability. L’regular maintenance is an investment that helps avoid high repair costs in the long term.

Thorough cleaning

Cleaning should be done according to the manufacturer’s recommendations, paying particular attention to the print heads to avoid blockages and to the rollers to prevent traction problems with the paper or print media.

Inspection and lubrication

A visual inspection makes it possible to detect possible anomalies. Furthermore, the lubrication moving parts is essential to reduce friction and wear.

Firmware and software update

Regular updates of the firmware and printer software guarantee optimal and secure operation.

Consumables management

The use of consumables high quality and recommended by the manufacturer guarantee not only superior print quality, but also greater longevity of the printer.

To conclude, never underestimate the importance of preventing breakdowns and regularly maintaining your industrial printers. As a professional, it is your duty to ensure that your equipment is always in optimal condition to ensure flawless efficiency and productivity. Taking the right steps now will save you a lot of hassle in the future.

Leave a Reply